Aerospace

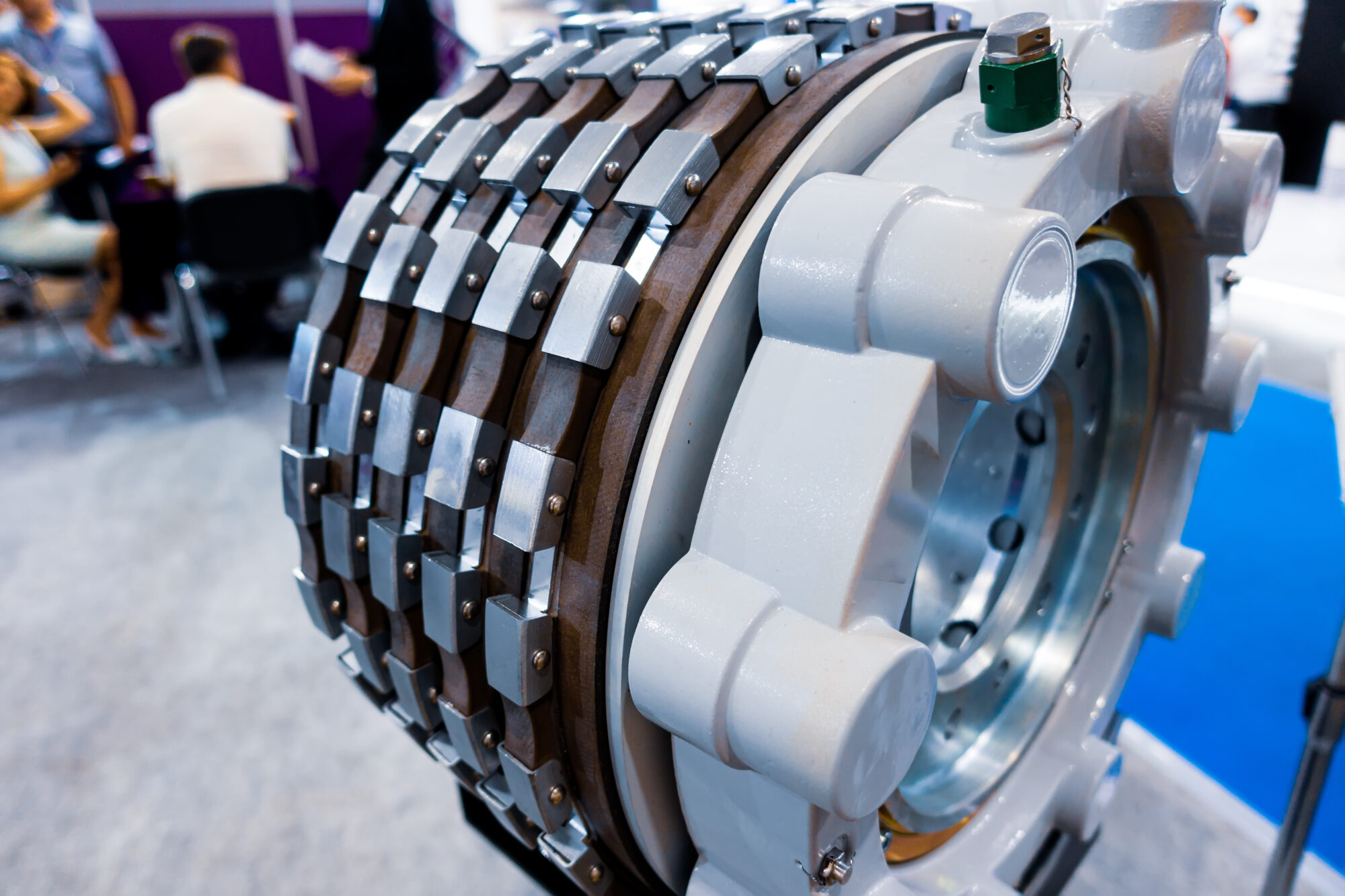

Carbon/Carbon brake systems for aerospace

Precision Aerospace Engineering Trusted in the UK

Wyken Engineering s the ideal AS9100-certified partner for aerospace component manufacturing, supporting commercial aviation, military aircraft, business jets, and aerospace research. For over twenty years, we have delivered flight-critical solutions with reliability and quality at the forefront.

Operating from our state-of-the-art Warwickshire facility, we serve major aerospace OEMs, MRO providers, and defence contractors across the UK. Our commitment to precision, traceability, and compliance makes us a trusted supplier for programmes where failure is not an option.

Aerospace Brake System Expertise

When it comes to aircraft brakes, Wyken Engineering stands at the forefront of carbon brake disc technology. We specialise in carbon brake disc machining that fundamentally transforms how carbon composites are processed.

This expertise is particularly critical for Aircraft On Ground (AOG) situations, where rapid turnaround of brake components can mean the difference between aircraft availability and costly downtime. Our processes minimise risks like delamination and enhance brake reliability, supporting operators who cannot afford component failures.

Carbon Brake Technology Applications

Aircraft brakes operate in extreme conditions—absorbing massive kinetic energy during landing, withstanding temperatures exceeding 600°C, and maintaining consistent friction properties across thousands of brake cycles. Our machining capabilities enable us to manufacture brake discs that meet these demanding requirements for:

- Commercial airliner main landing gear brake systems

- Business jet brake assemblies requiring rapid replacement

- Military fast-jet brake discs for fighter and trainer aircraft

- Helicopter brake systems for rotary-wing platforms

Ready to discuss your aerospace brake requirements?

Contact our technical team for application-specific consultation.

Integrated Aerospace Manufacturing

Beyond our specialisation in aircraft brakes, Wyken Engineering provides comprehensive precision manufacturing capabilities. Our facility is equipped with advanced multi-axis CNC milling and turning centres, alongside specialist grinding facilities for achieving the surface finishes and tolerances aerospace applications demand.

We routinely machine alloys and advanced composites, including:

Advanced Composites: Carbon-carbon materials for brake systems, structural elements, and thermal protection applications.

Aerospace-Grade Alloys: Aluminium 7075, stainless steel 15-5PH, and other certified materials specified in aerospace applications.

Every component we manufacture comes with full traceability and comprehensive batch documentation. This supports regulatory audits and ensures compliance with UK CAA, EASA, and international airworthiness standards. Our quality management system maintains complete material certification chains, from raw material suppliers through to finished component delivery.

Quality & Compliance Management

AS9100 certification isn’t just a badge for Wyken Engineering, it’s embedded in how we operate. Our comprehensive aerospace quality management system encompasses every stage of production, from initial quote review through to final dispatch.

First Article Inspection (FAI)

Every new component or design change undergoes rigorous FAI procedures, with dimensional verification, material certification, and process validation documented according to AS9100 requirements.

Material Certification

Complete traceability from mill test certificates through to component serial numbers, supporting airworthiness approvals and regulatory compliance.

Batch Traceability

Every production run is documented with unique batch identifiers, linked to material certificates, inspection records, and process parameters.

In-Process Verification

Statistical process control and automated inspection systems monitor critical dimensions during production, preventing non-conformances before they occur.

This quality infrastructure supports both defence and civil programmes, particularly those requiring secure UK supply chains and transparent documentation for airworthiness certification. For MOD programmes, we implement additional security protocols to handle classified component designs and sensitive programme information.

Our quality team works closely with customers during supplier approval processes, supporting FAIR submissions, AS9100 audits, and ongoing performance monitoring that keeps us on approved supplier lists.

Flexible Prototyping and Consultation

Innovation in aerospace often requires rapid iteration between design and manufacture. Wyken Engineering offers comprehensive prototyping services and design-for-manufacture (DFM) consultation that helps aerospace programmes move from concept to certified production efficiently.

Our technical team brings decades of aerospace manufacturing experience to the table, assisting with:

Legacy Aircraft Parts Re-engineering

When original suppliers are no longer available or drawings are incomplete, we provide reverse engineering services combined with modern manufacturing techniques. This supports operators maintaining older aircraft types where parts availability becomes increasingly challenging.

Programme-Specific Optimisations

Working directly with design engineers, we advise on manufacturing approaches that reduce costs, improve reliability, or enable previously impossible geometries through our ultrasonic composite machining capabilities.

Fast-Track Development

Priority manufacturing slots enable rapid prototyping cycles, supporting compressed development phases for new aircraft programmes or urgent modifications to existing platforms.

Obsolescence Management

As aircraft programmes extend beyond their original design lives, component obsolescence becomes inevitable. Our flexible manufacturing approach and material expertise enable us to provide sustainable solutions that keep aircraft flying.

This consultation extends throughout the component lifecycle. Whether you’re developing a new aircraft brake system, upgrading existing components, or managing obsolescence challenges, our engineering team provides technical support that goes beyond simply making parts to specification.

Exploring a new aerospace project?

Speak to our engineering team about prototyping and DFM consultation.

Why Choose Wyken Engineering for Aerospace Components?

Over seven decades of continuous aerospace manufacturing have taught us what truly matters: uncompromising quality, absolute reliability, and responsive technical partnership. We understand that aerospace components aren’t just parts—they’re critical elements in safety systems where lives depend on performance.

Our combination of AS9100-certified quality systems, advanced ultrasonic composite machining technology, and comprehensive precision engineering capabilities positions us as a single-source solution for aerospace manufacturers and operators. From carbon brake discs for aircraft brakes to complex machined components in exotic alloys, Wyken Engineering delivers the precision aerospace programmes demand.

Based in the heart of the UK’s advanced manufacturing region, we provide secure, traceable, UK-based production that eliminates international supply chain risks while supporting domestic aerospace and defence industries.

Let’s discuss how Wyken Engineering can support your aerospace programme.

Contact us today for technical consultation and quotation.